INTEGRAL QUALITY MONITOR

The future of Radiation Therapy Verification is here

- Unrivaled accuracy

- Real-time results

- Without any user interaction

2 minutes

Every 200ms

Real-time

Independent QA

The IQM detector independently measures a segment dose fluence at every control point and verifies it against the IQM reference signal. In real-time. The IQM reference signal is calculated from the imported treatment plan with a dedicated IQM calculation algorithm.

Real-time verification

Unrivaled accuracy

For even the most complex treatment techniques.

Completely integrated

Automated background monitoring. Without any user interaction.

Seamlessly integrated

For every QA task

IQM is the most versatile verification system available on the market. Fully automated workflow for Fraction QA, Plan QA and Machine QA. Seamlessly integrated. With unrivaled accuracy.

Fraction QA with IQM

Plan QA with IQM

Machine QA with IQM

Short-term signal reproducibility

Long-term signal reproducibility

R2 = 1.0

Signal is proportional to dose

0.2%

A true innovation

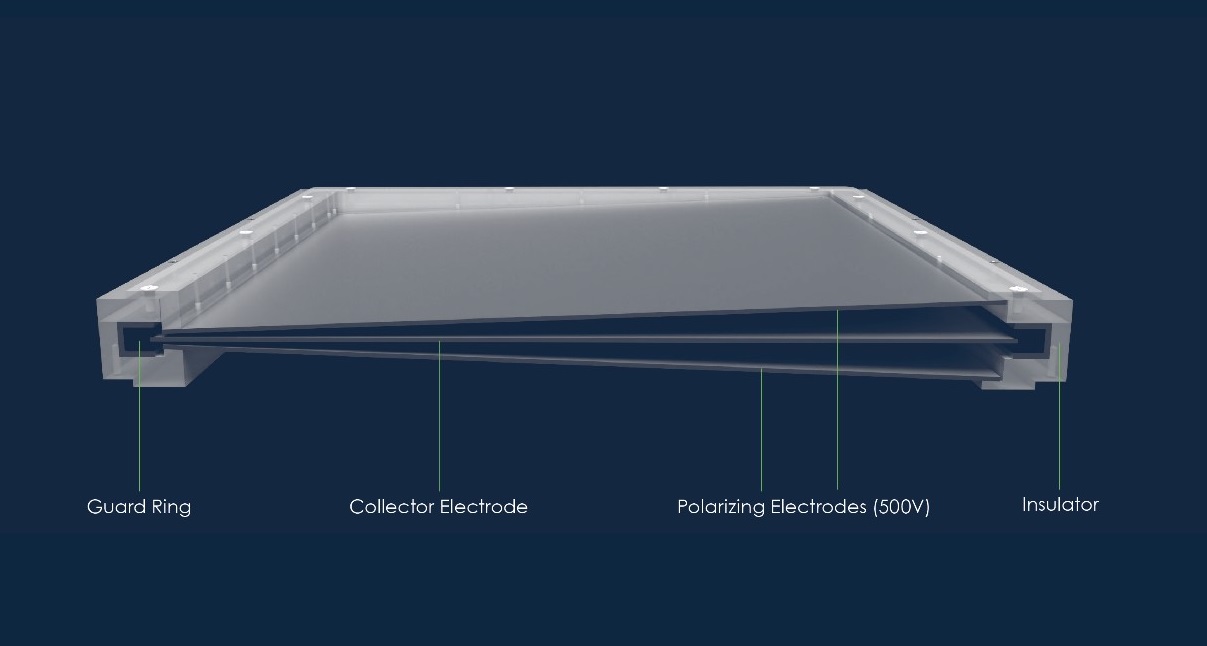

IQM combines the signal stability and reproducibility of a large ionization chamber with the spatial accuracy and sensitivity of film.

Significant time savings

The first fully automated end-to-end verification process. No user interaction required. No additional workload. As soon as the beam is delivered, the verification is done. IQM saves time and clinical resources at every step of the QA process.

Specifications

Ion chamber volume

550cc

Active Size

26.5cm x 26.5cm

Minimal / Maximum Field Size:

Unlimited to 40cm x 40cm

Detector Resolution

Continuous spatial resolution

Energy range

Photon energies from 1MV to unlimited (including FFF)

Dynamic range

Between 50 counts / minute and 5.000.000 counts / minute

Air Kerma correction

Built-in Thermometer and Barometer

Inclinometer (built-in)

Inclinometer resolution: 0.1°

Gantry / collimator angle resolution: 1°

Battery

4 Lithium-Ion batteries (medical device certified)

Battery life: >24 hours

Dimensions

45cm x 35cm x 3.5cm

(17.7” x 13.8” x 1.37”)

Weight (incl. battery)

4.3kg (9.48lb)