Presentation Summary

Luis Fong de los Santos, PhD, presented the preliminary results of a multi-center workgroup to implement TG-142 Machine QA with IQM at this year’s ASTRO conference.

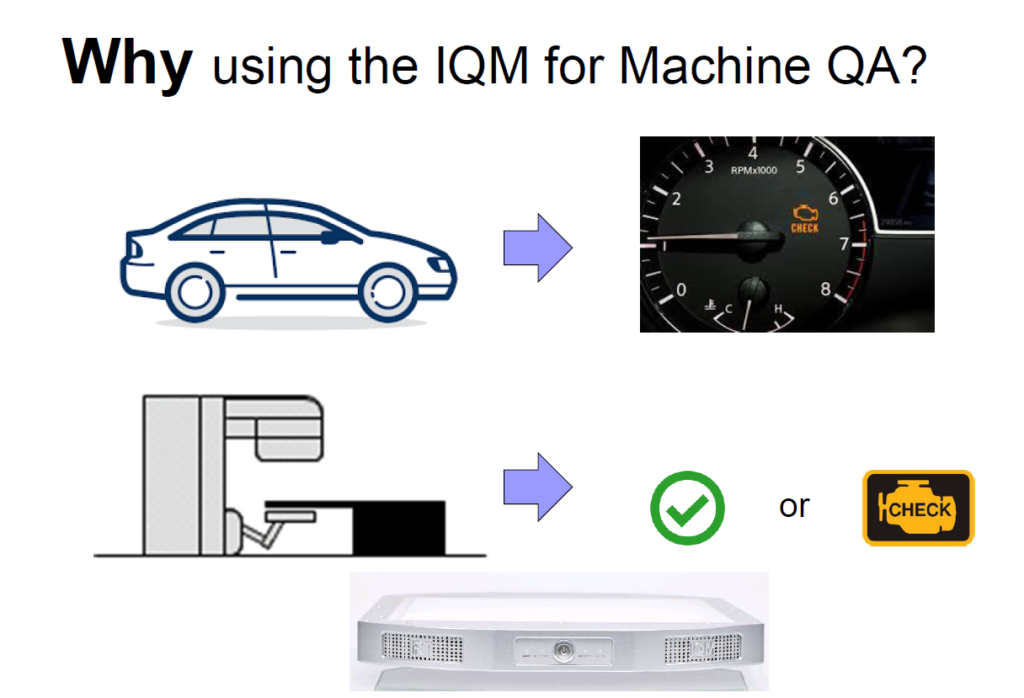

He began with the question, “Why use IQM for my Machine QA? What is the purpose of it…?”

Dr. Fong compared IQM to the engine light in your car. “This is not a diagnostic tool, it just tells you that there is something wrong with your car. It is very simple, it is easy to understand, in terms of ‘there is a problem’, but it does not give you more information than that.”

He explained that using IQM for Machine QA similarly tells you if everything is okay or if you need to check your machine, noting that IQM’s approach to Machine QA follows a different paradigm that current QA tools.

Dr. Fong described how he and his colleague collaborated with physicists from Princess Margaret Hospital (in Toronto) and Cedars Sinai (in Los Angeles) to implement TG-142 with IQM. “So, what can we check? The first thing we asked ourselves was, what can we check?”

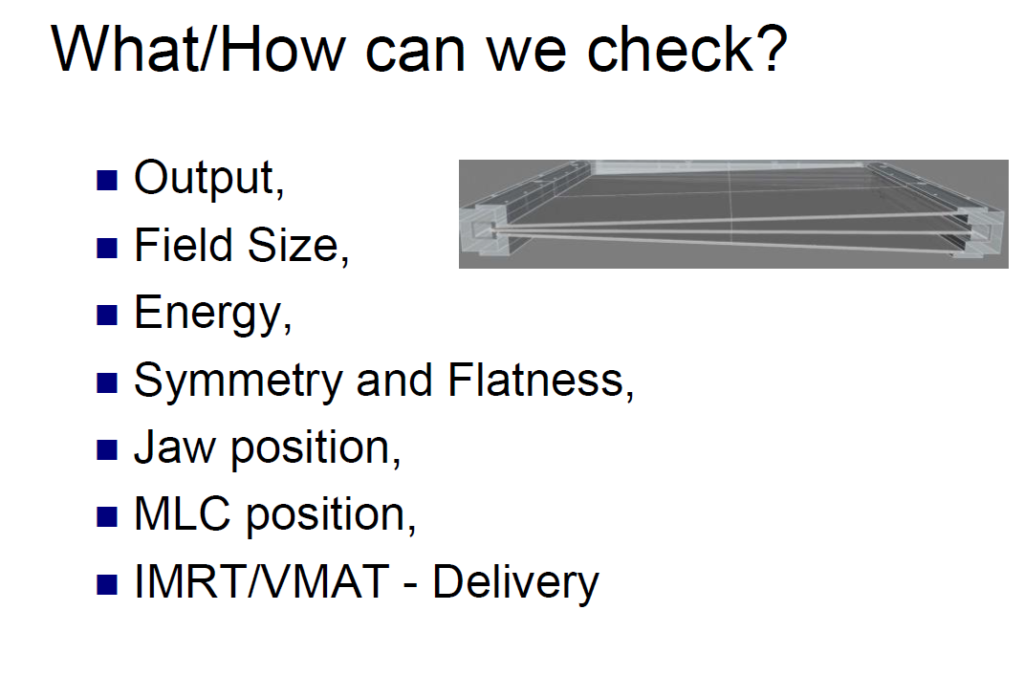

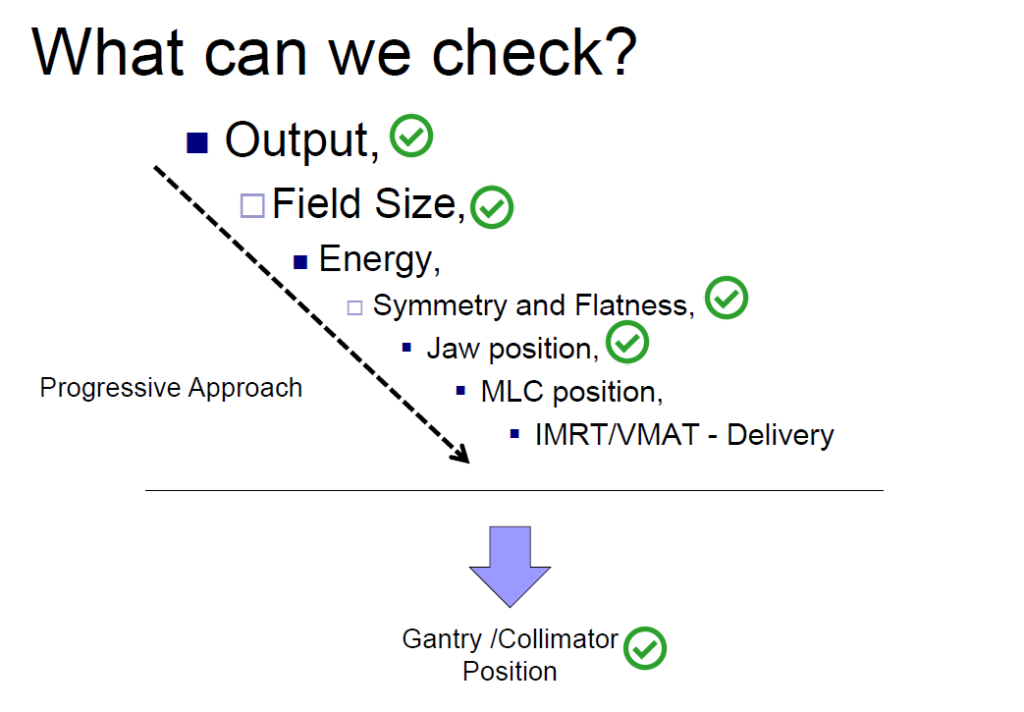

“So, what can we check? The first thing we asked ourselves was, what can we check?” The team reviewed the AAPM Task Group 142 report on Machine QA, the standard, and considered which of the checks could be done with the IQM System. They isolated these ones: output field size, energy, symmetry flatness, jaw position, MLC position and IMRT/VMAT delivery.

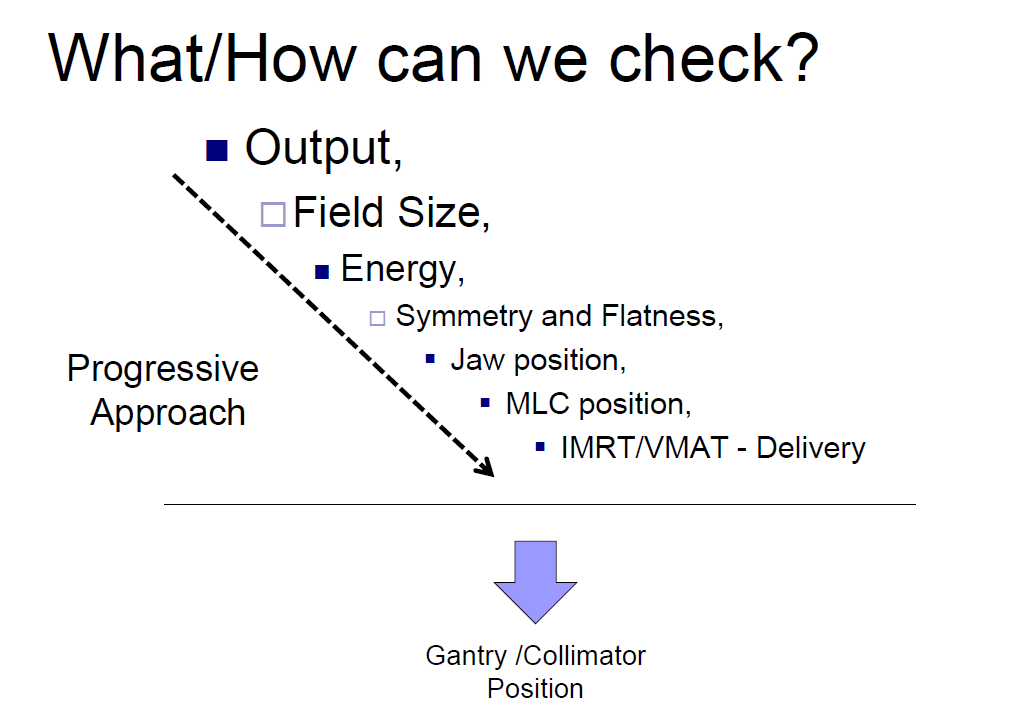

The team reviewed the AAPM Task Group 142 report on Machine QA, the standard, and considered which of the checks could be done with the IQM System. They isolated these ones: output field size, energy, symmetry flatness, jaw position, MLC position and IMRT/VMAT delivery. Next the team decided to take a progressive approach, starting with the most basic QA tests of machine output and field size, symmetry and flatness, extending through jaw and MLC position verification to IMRT and VMAT QA.

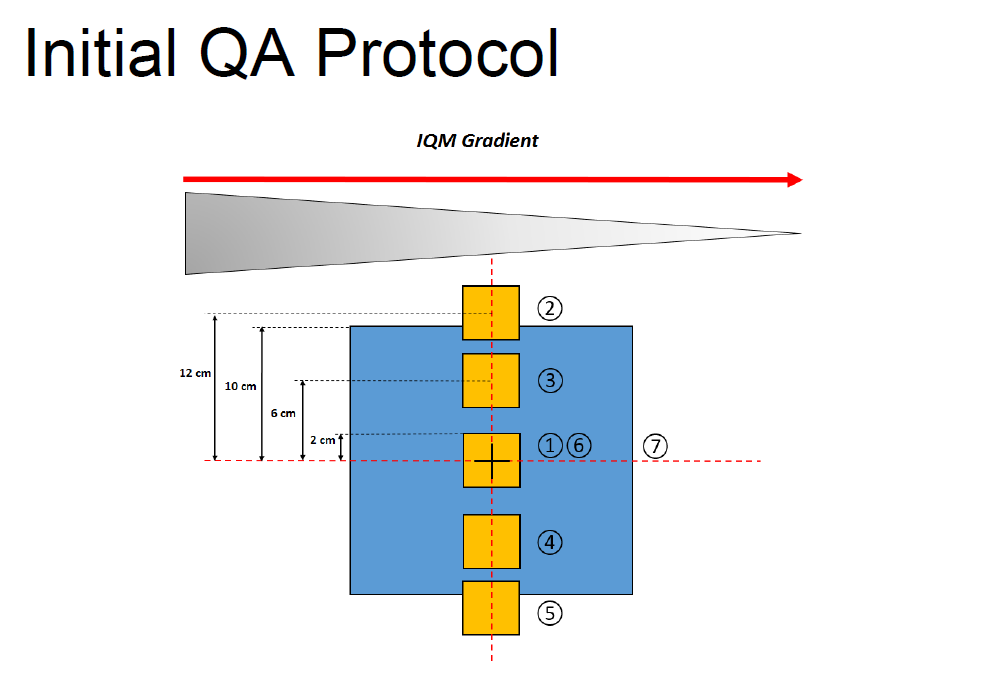

Next the team decided to take a progressive approach, starting with the most basic QA tests of machine output and field size, symmetry and flatness, extending through jaw and MLC position verification to IMRT and VMAT QA.  Dr. Fong noted that because the IQM is in the gantry and encompasses the entire field, QA can be done at any geometry: any field size, shape and position, any collimator and gantry position. And that IQM’s easy setup also reduces the setup uncertainties that are a constant challenge when you do traditional Machine QA. He then illustrated the initial QA protocol the working group devised to evaluate beam output, field size, symmetry and flatness.

Dr. Fong noted that because the IQM is in the gantry and encompasses the entire field, QA can be done at any geometry: any field size, shape and position, any collimator and gantry position. And that IQM’s easy setup also reduces the setup uncertainties that are a constant challenge when you do traditional Machine QA. He then illustrated the initial QA protocol the working group devised to evaluate beam output, field size, symmetry and flatness. The measurement protocol starts with a reference field and then delivers a series of apertures in a specific order. “We start with something in the center and then moving across, and then going big and then going small, in order to isolate different components.”

The measurement protocol starts with a reference field and then delivers a series of apertures in a specific order. “We start with something in the center and then moving across, and then going big and then going small, in order to isolate different components.”

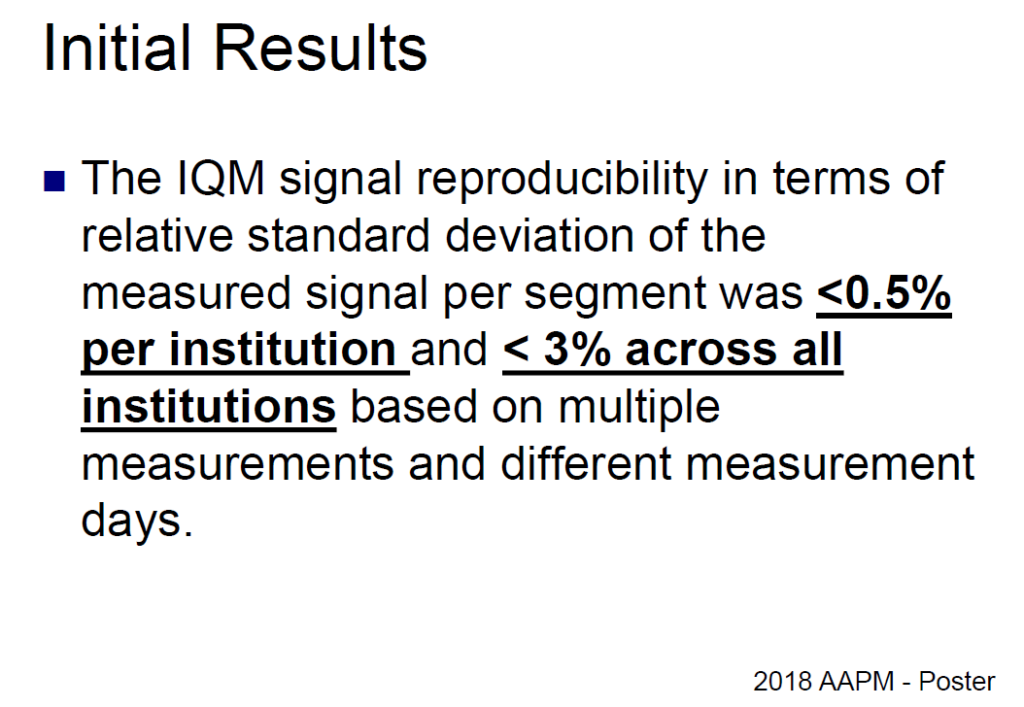

Dr. Fong commented on the consistency of measurement results at each site and across sites: “When we were doing this testing, a single institution would run this protocol many, many times and the test was very consistent, to about half a percent (0.5%). The interesting thing is that across all of the other institutions was that when we compared our data, it was within about 3%. That is actually very, very neat.”

Dr. Fong commented on the consistency of measurement results at each site and across sites: “When we were doing this testing, a single institution would run this protocol many, many times and the test was very consistent, to about half a percent (0.5%). The interesting thing is that across all of the other institutions was that when we compared our data, it was within about 3%. That is actually very, very neat.”

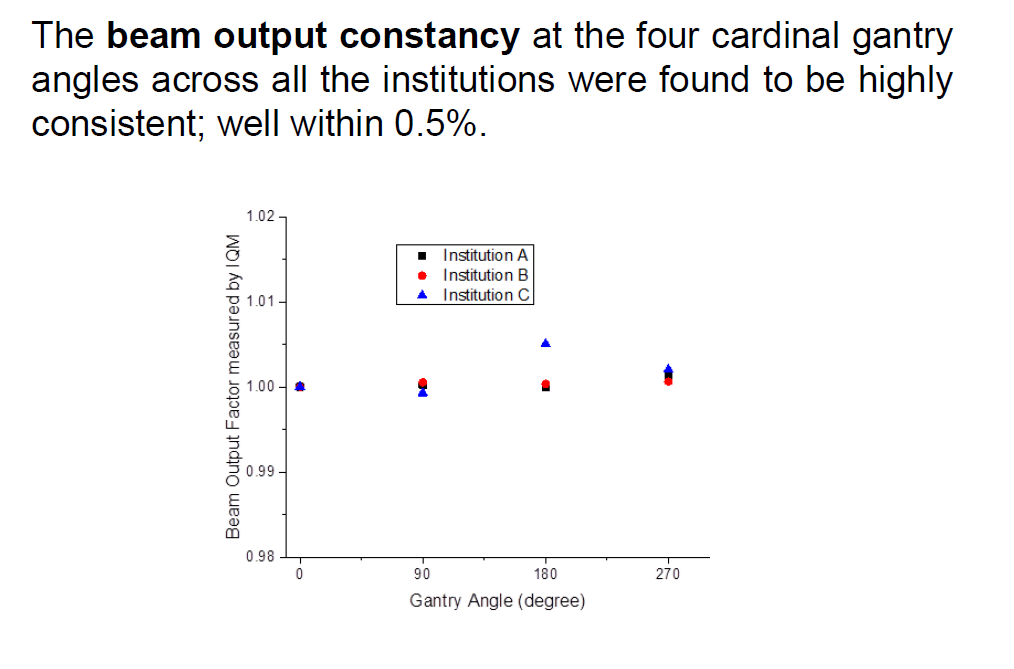

The beam output constancy was within very tight agreement across the three institutions, with the exception of one institution at one gantry angle – and this ‘outlier’ was still within 0.5% of the other sites.

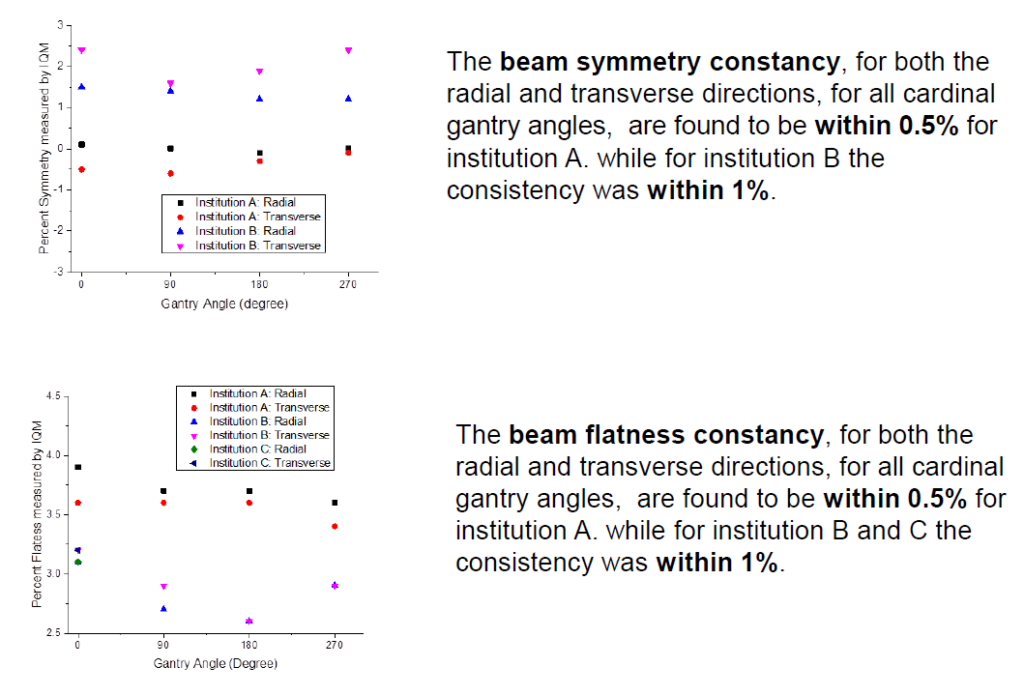

The beam output constancy was within very tight agreement across the three institutions, with the exception of one institution at one gantry angle – and this ‘outlier’ was still within 0.5% of the other sites.  After reviewing the beam output evaluation, Dr Fong highlighted beam symmetry and flatness. The delivery protocol evaluates symmetry by finding the difference between the two points farthest away in the protocol setup shown above. To evaluate flatness the protocol compares the five points across the field to the center. Within each institution the symmetry and flatness results were consistent with measurements taken with their traditional QA methods.

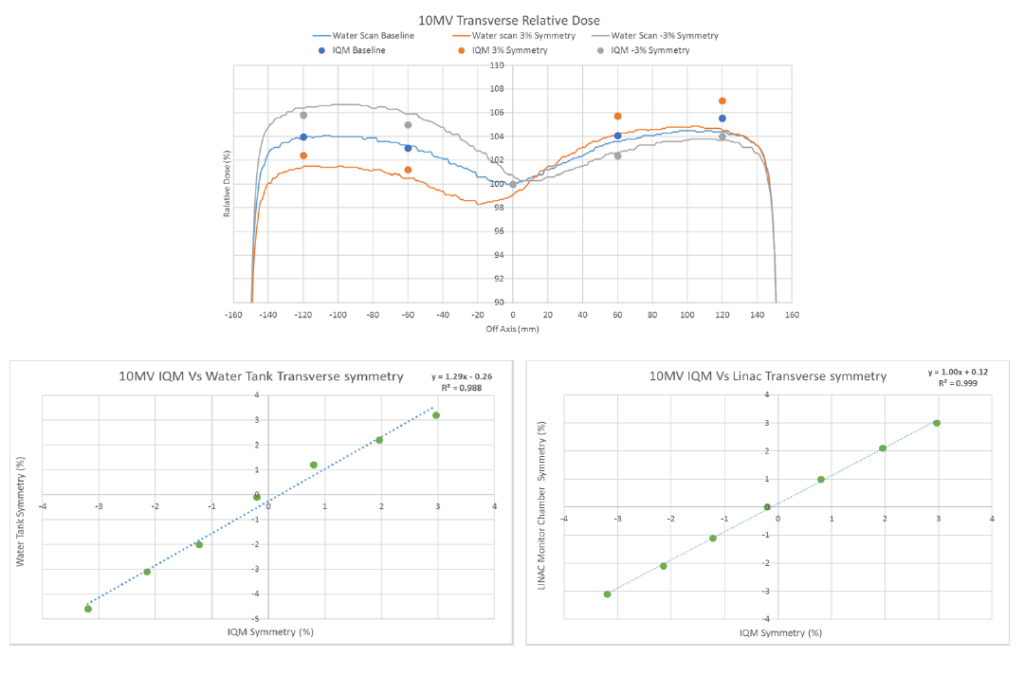

After reviewing the beam output evaluation, Dr Fong highlighted beam symmetry and flatness. The delivery protocol evaluates symmetry by finding the difference between the two points farthest away in the protocol setup shown above. To evaluate flatness the protocol compares the five points across the field to the center. Within each institution the symmetry and flatness results were consistent with measurements taken with their traditional QA methods.

One institution introduced asymmetry into the field and compared the IQM results to water tank scans made with the same asymmetries, finding excellent agreement. That site further compared the linearity of IQM results against both the water scans and the linac’s own ion chamber and found both to be strongly proportional.

Dr. Fong stated that the group’s work so far indicates that the IQM system can detect output, field size, symmetry and flatness deviations as long as they have a reference delivery of the protocol at known calibration conditions.

Dr. Fong stated that the group’s work so far indicates that the IQM system can detect output, field size, symmetry and flatness deviations as long as they have a reference delivery of the protocol at known calibration conditions.

The group is currently working to extend the delivery protocol to evaluate the MLC leaf positioning. Their approach is to break traditional tests like the picket fence test into component deliveries that can isolate sections of the MLCs across multiple positions, according to Dr Fong. He described preliminary tests with the extended protocol and introducing errors and said that the system can detect those errors.

The group is currently working to extend the delivery protocol to evaluate the MLC leaf positioning. Their approach is to break traditional tests like the picket fence test into component deliveries that can isolate sections of the MLCs across multiple positions, according to Dr Fong. He described preliminary tests with the extended protocol and introducing errors and said that the system can detect those errors.

Dr. Fong concluded his presentation describing his view of IQM’s added value. He noted that the system was effective for assessing a single machine on a single day, but said what excited him was the possibility of comparing QA results across multiple machines – at a single site or many sites, in a single state or country or spread across the globe, over time.

“…If you have a specific protocol that you are running, you can do the measurement there and you can do the measurement here and you should expect to get the same result. Which I think is very powerful.” “We do have quite a few [machines] and I am very excited to do more testing on this to understand if [IQM] actually can tell me that all of my machines are performing exactly the same way,” said Dr. Fong. “I am very excited to continue working on this because I think it has a lot of potential.”

“We do have quite a few [machines] and I am very excited to do more testing on this to understand if [IQM] actually can tell me that all of my machines are performing exactly the same way,” said Dr. Fong. “I am very excited to continue working on this because I think it has a lot of potential.” Dr. Fong wrapped up by discussing that the results IQM gives are not in the form physicists are used to seeing but contain the same information, as well as that IQM cannot capture all the parameters that TG-142 requires but can do many of them efficiently and with a simple setup. And he acknowledged his workgroup partners:

Dr. Fong wrapped up by discussing that the results IQM gives are not in the form physicists are used to seeing but contain the same information, as well as that IQM cannot capture all the parameters that TG-142 requires but can do many of them efficiently and with a simple setup. And he acknowledged his workgroup partners:

- John De Marco at Cedars Sinai

- Andrew Veres at Mayo Clinic

- Princess Margaret team:

- Mohammad Islam

- Makan Farrokish

- Rob Heaton

- Will Roestel (iRT) – group coordination