Our last newsletter outlined how real-time verification of hypo-fractionated treatments with IQM allows sites to implement this new technology with confidence and how it improves patient convenience without compromising patient safety. (Read the complete article.)

Providing optimal care to cancer patients is an increasingly complex task. Continued growth in the number of cancer patients combined with an increasing complexity in treatment techniques, therapy equipment and clinical processes creates a constant stream of new demands and challenges.

Hypo-fractionation is one way of addressing these demands and challenges, significantly reducing treatment time, and saving clinical resources while improving patient convenience.

Minimizing the time and resources allocated to Quality Assurance increases clinical efficiency, if it can be done without sacrificing the quality of the QA performed.

The growing clinical complexity puts new and increasing demands on clinical Quality Assurance: Hypo-fractionation significantly raises the severity of potential treatment delivery errors. Stereotactic treatment techniques require enhanced spatial sensitivity. Plan adaption multiplies the number of quality assurance tasks.

Conventional Quality Assurance addresses these new challenges by introducing additional tools specifically designed for these new challenges. Additional tools create additional workload and place new demands on time and clinical resources.

In contrast, the Integral Quality Monitor (IQM) System provides a new level of versatility allowing you to address the increasing complexity of clinical quality assurance while at the same time minimizing the time and resources required for QA.

„The IQM is an automated tool that breaks the complexity of modern systems and delivery techniques by providing an independent and highly precise tool to monitor the accuracy of the delivery.“

Luis Fong de los Santos, Ph.D., Medical Physicist

at Mayo Clinic, Rochester, USA

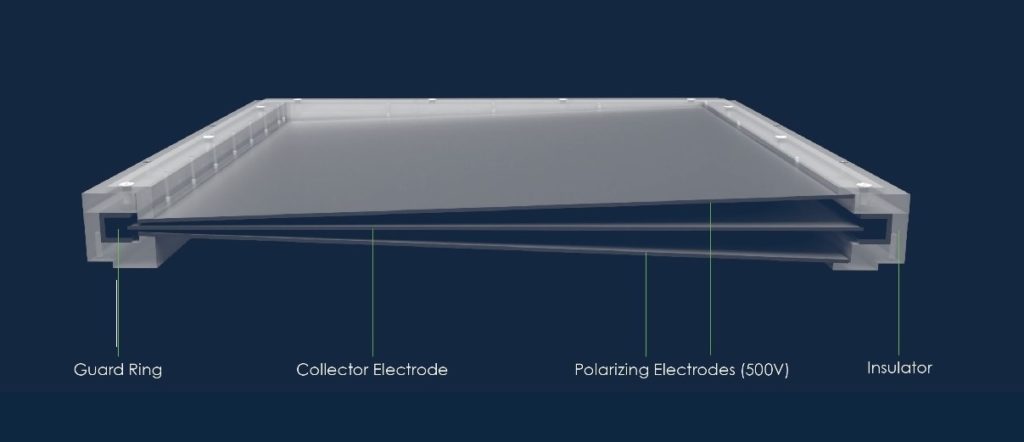

The IQM detector’s new and innovative design provides unmatched spatial sensitivity supporting the verification of even the smallest available stereotactic field size. IQM supports the most complex treatment techniques by uniquely verifying the accuracy at every single control point. IQM overcomes the constraints of conventional QA by verifying any clinical field size, any field shape at any position, any dose, any dose rate, any photon energy (incl. FFF), any leaf motion, any gantry and collimator angle, any parameter that constitutes the treatment beam without any limitations.

IQM offers a new level of accuracy for every treatment technique from stereotactic treatment techniques to large field (up to 40cm x 40cm) IMRT techniques, from complex VMAT/Rapid Arc techniques to TBI. IQM verifies high dose rate hypo-fractionated treatments and supports gated treatment techniques. A single QA system for ALL your photon treatments.

The new and innovative IQM detector design provides 100% active detection area. IQM always measures 100% of the treatment beam independent from field size, field shape, leaf motion, beam position, etc. No interpolation and absolutely no extrapolation is required. The unmatched signal reproducibility of the innovative IQM Detector design ensures unrivaled detection accuracy at every measurement, independent from factors like linac type, treatment technique, user experience, etc. And unlike log-file based systems, IQM’s completely independent data stream detects not just random delivery errors, but also systematic delivery errors like leaf bank miscalibration.

Even more importantly this unmatched verification accuracy and versatility works COMPLETELY AUTOMATED in the background. It takes less than 10 seconds to setup IQM and from there the entire QA process happens automatically. From the import of the treatment plan to the automatic calculation of the expected reference signal utilizing a new and independent calculation algorithm. From patient synchronization with the linac control system to the automated acquisition of the delivered signal and the real-time verification of the delivery accuracy at every control point. From automated detection of any clinically significant deviation between the prescribed and the delivered dose to the automated generation of comprehensive verification reports. Every single step works completely automated and WITHOUT ANY USER INTERACTION.

„The quick setup and fully automated handling of all clinical data

significantly reduces the time we need for Plan QA.“

Otto Sauer, Ph.D., Head of Medical Physics

at University of Würzburg, Würzburg, Germany

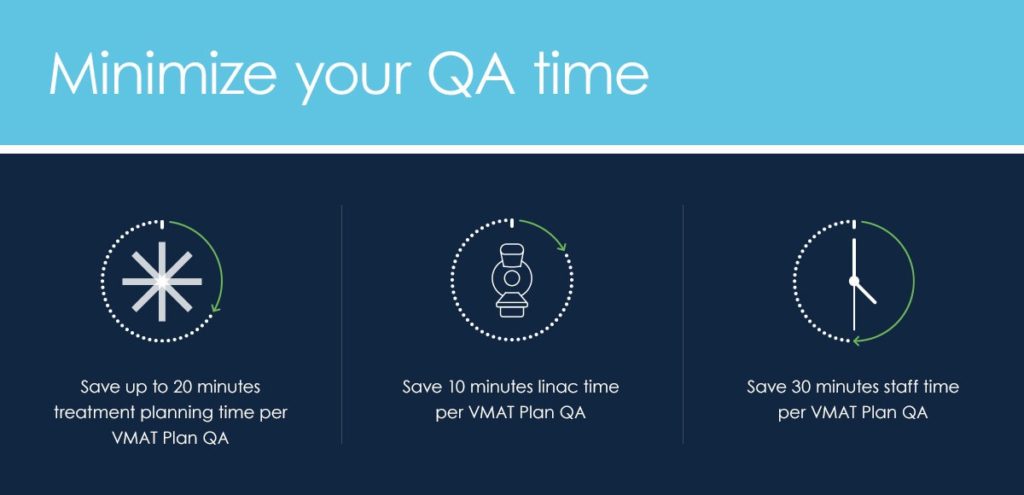

The complete automation of the IQM system significantly reduces the time needed for every step of your QA process. IQM eliminates the need for specific QA plans at the TPS. IQM eliminates tedious QA device setup, QA device alignment and QA device calibration. IQM saves time by avoiding artifacts introduced by panel sag, auto-alignment, and volume averaging. IQM’s real-time verification eliminates any post-treatment data processing or analysis. Verification is completed as soon as the beam stops. IQM automatically creates the verification report and sends it as a PDF via e-mail.

„IQM saves us 400 hours planning time, 200 hours linac time and 600 hours staff time compared to our conventional 3D arrays.“

Mohammad Islam, Ph.D., Medical Physicist

at Princess Margaret Cancer Centre, Toronto, Canada

IQM allows you to address the increasing complexity of new treatment techniques while reducing the time needed for QA. IQM allows you to focus your time and clinical resources on providing the best possible care for your patients.

„IQM allowed us to reduce our plan QA time from 21 minutes per VMAT plan to less than 3 minutes per day.“

Marlies Pasler, Ph.D., Medical Physicist

at Lake Constance Radiation Oncology, Friedrichshafen, Germany

„IQM saves us more than 90 minutes plan QA time.

Every day.“

Friederike Ehland, Head of Medical Physics

at Zentrum für Strahlentherapie und Radioonkologie, Bremen, Germany

If you would like to learn how IQM helped the team at GenesisCare Spain to reduce their QA time during the Covid-19 crisis click here to read the complete article.

And remember, this automation also works for dosimetric machine QA tasks.

IQM provides machine QA protocols stored as treatment plans to be periodically delivered by the Radiation Therapist. Dose constancy, beam symmetry, beam flatness, energy constancy, picket-fence tests, leaf speed tests, leaf position accuracy, leaf gap verification, leaf transmission, beam matching verification, and more tests are completely integrated, requiring only that the plan be loaded at the linac control console. Everything else works fully automated in the background.

„This allows everyone to stay ahead of the game of QA…“

Stanley Benedict, Ph.D. Professor & Vice Chair of Clinical Physics

at University of California at Davis Comprehensive Cancer Center, Sacramento, USA

IQM makes Quality Assurance an integral part of the treatment planning and delivery process. IQM removes the boundaries between treatment processes and quality assurance processes. IQM requires no specific user knowledge and/or user experience, making this new and innovative QA technology available to any radiation therapy clinic anywhere in the world. IQM provides clinics with extensive QA programs new insights into their treatment delivery accuracy, allowing them to further improve their clinical outcomes and provide optimal care to their cancer patients.

Please contact us for more information or to setup a presentation for you and your colleagues.